Deck: Ready to make a facility’s CNC lathe time maximally efficient? Cut costs and boost productivity with these proactive tips.

Computer numerical control (CNC) machines play important roles in creating everything from smartphones to semiconductors. Once factory leaders figure out the CNC cycle time calculation for each machine in a facility, they can determine whether the averages are within or outside expectations. If leaders determine they must decrease the CNC cost per hour, they have numerous roles to explore to boost efficiency.

They’ll likely get even better results by combining several strategies. It takes some time to see what works best, but patience and persistence enhance the chances of impressive improvements. Then, electronics manufacturers and others relying on CNC machines can become more competitive and able to adapt to new demands.

1. Streamlined layout

CNC machinists can best use their time when their workspaces reflect their tasks and the enterprise’s typical output. Strategically arranging the tools, machines, and other equipment to optimize people’s time and the flow of movement can make the facility and its workers better able to withstand increased demands or other challenges.

Factory managers should get feedback from workers to pinpoint aspects of their workflows that currently work well or provide preventable obstacles. When supervisors clarify they’re open to all suggestions, people should feel more open about speaking frankly and trusting that their superiors have their best interests in mind.

Decision-makers must also remember adjusting to new layouts takes time. Using a digital twin or design app could be a great way to eliminate common pitfalls and design the best factory workspaces with minimal hassles.

2. Optimization opportunities

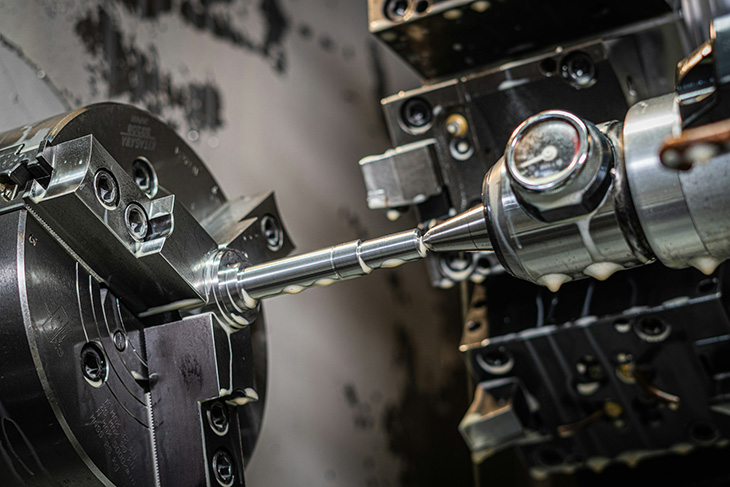

One rapid production facility director realized there were plenty of ways to shorten lathe time in his facility when he viewed the surroundings with a fresh perspective. A practical alteration was installing large change mechanisms holding up to 64 cutting tools. The director then put duplicates of some tools into the mechanisms, making it easy to switch to new ones once the old ones became too worn.

The director also optimized his facility by increasing the overall number of operating hours per machine. He realized partially automating the processes and creating new overnight shifts would increase workflow faster than hiring and training new team members.

Optimization possibilities will vary depending on the company, its number of employees, the type and volume of parts produced daily, and more. Considering all those factors will increase leaders’ confidence about what to change and when.

3. Automated processes

Many decision-makers find they can significantly reduce the average CNC machine cost per hour by automating parts of a factory’s processes. One best practice is to use automation to solve well-defined problems. For example, the bar feeders in one facility could not handle some particularly long or heavy parts. Leaders dealt with that issue by installing a robotic cell through which six parts run, keeping it at capacity.

Applying automation to CNC machines isn’t always a perfect solution. However, succeeding is all about understanding the possibilities automation can unlock, like how the robotic cell excels at handling the larger parts of components requiring two-sided cutting. The bar feeders achieve comparatively faster production speeds, but the robotic cell streamlines the handling of specific elements.

4. Thoughtful troubleshooting

CNC cycle time calculation outcomes are often the first and strongest indicators of the need for improved processes, but people must determine the root causes of what’s going wrong. In one example, a CNC facility serving electronics and other industries needed to keep pace with demand by increasing already-high output.

Decision-makers tackled that goal by identifying and studying problem areas in existing processes. One conclusion was that a specific milling machine prevented people from maximizing spindle time. Leaders addressed the matter with a cobot that caused a 32-hour boost in weekly machine usage time.

This approach also compensated for the hours lost due to employee breaks. Advanced machines can’t necessarily replace humans’ roles, but they can often supplement what people do.

5. Prioritized training

CNC machinists need ongoing learning programs to keep their skills sharp, and ensure they can competently work with new machine models. Creating a strong hands-on training program can help workers reduce errors, learn to spot problems and maximize the output of each machine. Supplementing this experience with online training programs teaching advanced uses of CAM software will also help workers grow their skills and adapt to industry changes.

With technology constantly evolving, it’ll be important to stay informed about how emerging technologies, like AI, will impact machining operations. AI can add value to CNC machines by analyzing and processing recurring patterns to improve parts production. Using AI-based machining software has the potential to improve efficiency during each project due to its ability to analyze the data from past projects and suggest ways to make adjustments. Real-time AI-driven analytics can give shop owners a competitive edge, so it’s important to train employees on how to utilize AI software.

Continuous improvement

Electronics manufacturers are in increasingly high demand, and those that can demonstrate consistently reliable performance will have the best chances of staying profitable and agile in the modern marketplace. Besides using these five tactics, people should periodically evaluate what’s working well and how they can continue improving. Analyzing those statistics will keep everyone simultaneously challenged and motivated while showing them lathe time efficiency is a collective effort.