Automatic selection of picosecond or femtosecond laser depending on the application and component material

The demand for components of high quality in large quantities and the shift of value chains to regions with low production costs are putting competitive pressure on many manufacturing operations. Often the only way to absorb this is through faster manufacturing methods. This however requires modern technologies with a high degree of automation, which seem oversized for small to midsize enterprises (SMEs) in particular. Frequently the procurement costs, for instance for ultra-short pulse laser systems, are simply too high. GFH GmbH and neoLASE GmbH jointly developed a cost-effective, cross-industry solution under the EU subsidy programme “Horizon 2020”: the “Smart Modular All-in-One Robust Laser Machining Tool” – SMAART – is a highly flexible, fully automated laser machining system that automatically switches between various process steps such as laser turning and fine texturing using an especially programmed, intelligent control unit. The system also covers a pulse range of 500 ps to 500 fs with no need for complex changeovers. This keeps the acquisition cost down, and is intended to increase quantities and create jobs over the long term.

When production or personnel costs go up, many operations are forced to restructure their production processes or to outsource them entirely. Especially countries with lower wages and operating costs outside the European Union are attractive for German companies in this context. “This means the European region loses a significant amount of potential sales and added value,” explains Anton Pauli, CEO of GFH GmbH. “According to calculations based on World Bank data, about nine billion euros have been lost to migration to low-wage countries in recent years alone.” In order to counteract this trend, the European Commission is promoting new technologies to make production processes more efficient and therefore cost-effective through initiatives and tender offers such as the Horizon 2020 campaign.

One of these technologies is workpiece machining using ultra-short pulse lasers that operate with high precision, contactless and therefore gently. To date such systems have not only been very expensive, their structure was also complex and they were limited to single production steps. This meant different systems often had to be purchased for different manufacturing methods, or complex and time-consuming changeovers were required. Extensive know-how of the laser technology and control was also required in order to deliver optimal results. To date this not only made the technology uneconomical for SMEs, but also inhibited the willingness to invest. The two laser specialists GFH GmbH and neoLASE GmbH joined forces with the goal of jointly developing a machining system. With SMAART, a system was developed that can be integrated into GFH GmbH’s new machine types, offering the appropriate laser selection – picosecond or femtosecond laser – via the input interface according to the material being processed and the machining process, and generating the correct process parameters. This improves efficiency and broadens the production scope without comprehensive specialised knowledge in the field of laser machining. “Faster amortisation can be achieved as a result, making the establishment of laser machining as a key technology for the entire material processing sector realistic,” explains Maik Frede, CEO of neoLASE GmbH. The ambitious project was financed among other things with funds from the European Union Horizon 2020 framework programme. GFH and neoLASE with their SMAART project were chosen over 1658 competitors.

Flexible amplifier design enables variable pulse duration and performance classes

At first there was just a vague idea that emerged at a laser networking meeting. “An exchange of experiences after the event revealed that laser technology is predestined for such a project,” Pauli explains. “Thanks to contactless, flexible processing using lasers without noteworthy thermal conduction, the technology also has the potential to replace energy-intensive processes.” First the two companies had to precisely define the challenges, market situation, technical status quo and required development steps. “To make the implementation of such a project possible in the first place, we had to make the laser technology more accessible to the customer and minimise its complexity,” Frede explains.

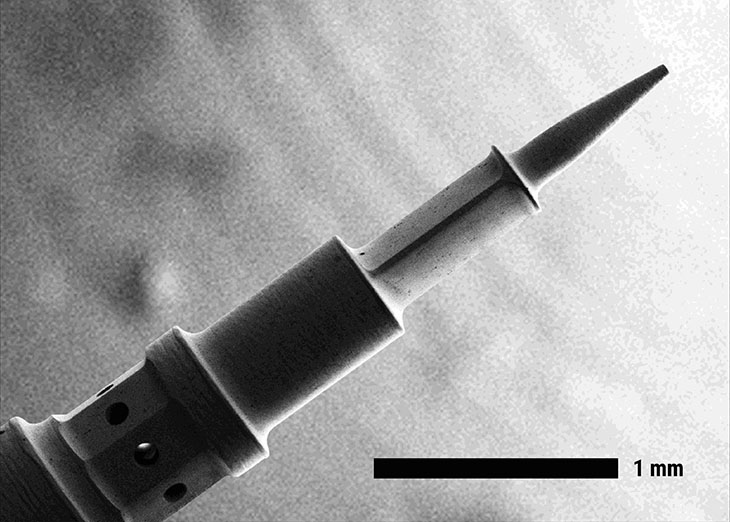

To guarantee a high level of flexibility – switching between various process steps and laser parameters without changeovers – a universal laser source had to be provided for machining, with rapid, automated adaptation of the pulse duration and intensity. The machines with integrated SMAART tool have a type of own intelligence that automatically identifies the respective parameters and components for the individual machining steps, with no need for an operator to calculate these in advance and manually enter them in the control unit. “This control centre was supplied to us by neoLASE with its GAP module,” Pauli reports. “Thanks to the flexible amplifier design, different pulse durations and performance classes can be called up on our GL machines without having to integrate CPA or regenerative amplifiers in addition.” This makes a compact layout possible for the machines, which are nevertheless capable of generating pulse energies of up to 400 µJ and an average output of 80 W. Additional costs due to more complex lasers or components are simultaneously avoided. “The machining systems from GFH are generally designed for modularity and flexibility, making them perfect for our amplifier modules,” Frede confirms. Since the combination of the two technologies covers the pulse range from 500 ps to 500 fs and fast switching is guaranteed, the system is able to achieve significant speed increases and quality improvements. Further optimisation of the removal rate is even conceivable through the simultaneous use of picosecond and femtosecond pulses.

Contactless machining replaces energy-intensive processes

Contactless laser machining contributes to this as well: the pulses are so short that there is no noteworthy thermal conduction, meaning that melting of the material, microstructure changes, phase changes and thermal stresses in the work piece are avoided. “This opens up a broad field of application for the production of micro-components, not only in classic mechanical engineering but also for various industries such as medical technology or the textile and watch making industries,” Pauli explains. “In the ideal case, energy-intensive or ecologically questionable processes can be replaced.” This is particularly important when the objective is to produce consistently high quality in large quantities without increasing the production costs.

In order for the desired flexibility to actually be given from the outset, the SMAART-capable machines – in addition to the optimised hardware – also have an integrated database that stores various process parameters such as the pulse duration, traverse path of the optics, work piece dimensions and type of material. This makes it possible to choose from over 100 manufacturing methods for laser drilling, laser cutting, texturing and laser material removal for metal, ceramics, glass and polymers via the input interface. “The user can simply initiate the desired process step at the push of a button. Then the machine is automatically positioned in the same mounting,” Frede explains. “When new applications or parameters that have not been defined yet are added, the machine and GAP are correspondingly adapted.” This means SMAART is subject to continuous further development and “learning”.

Focus on ease of use and quality control

To ensure consistently high work piece quality, even with difficult to process materials such as diamond, SMAART-capable machines are equipped with online quality control as a tool that validates the process parameters during machining. This makes quality sampling possible even while the process step is being executed. “Rather than just optimising the laser technology, we wanted to boost the added value of these processes as much as possible, for example through simplified handling,” Pauli explains. “A reliable machine solution, ready for immediate universal production, keeps the operation competitive and enables long-term growth with no fear of personnel pressure or the need for investments.”