Capacitive operating systems that control industrial plants, check medical equipment or open doors in public transport, for example, have long been an integral part of everyday life. These systems, however, have disadvantages in that they are highly sensitive to water or extreme temperatures and suffer from rapid wear. They often have edges that are difficult to clean and where dirt and bacteria can settle. Their use was also previously limited to certain materials such as glass or plastic, which severely restricted the design possibilities. The DYNAFORCE Metal Touch input system can now solve these challenges. The operating system from the Swiss company Algra tec AG is free from dirt-collecting edges and is based on strain gauges. As a result, the touch buttons react much more sensitively to different levels of pressure. They can be used in conjunction with a wide variety of operating materials and are therefore ideal for particularly demanding and design-sensitive applications.

Scenarios in which capacitive touch-based input systems are used are extremely diverse: in addition to industrial applications, they enable doors in public transport or even sanitary facilities to be operated. But the limits to the supposed flexibility soon become apparent. “Anyone who has ever tried to control a capacitive input system on wet surfaces or while wearing gloves is likely to know that it often takes several attempts before the buttons respond. This is annoying, but more importantly this unreliable operation can also result in a considerable loss of time,” explains Joshua Fajardo, DYNAFORCE project manager at Algra tec AG. “This unreliability comes about because capacitive input systems find it difficult to detect touch when surfaces are wet or dirty.” The limited choice of materials is another disadvantage: capacitive input systems are limited to non-conductive control fronts, for which glass is well suited. Many other materials, on the other hand, do not work at all or only to a limited extent. Most input technologies are not compatible with materials such as wood or metallic surfaces. However, if the control element is to be used in lifts, for example, there are legal standards on vandalism resistance that need to be met and the systems must be correspondingly robust.

Strain gauge-based input system opens up new surface materials for use

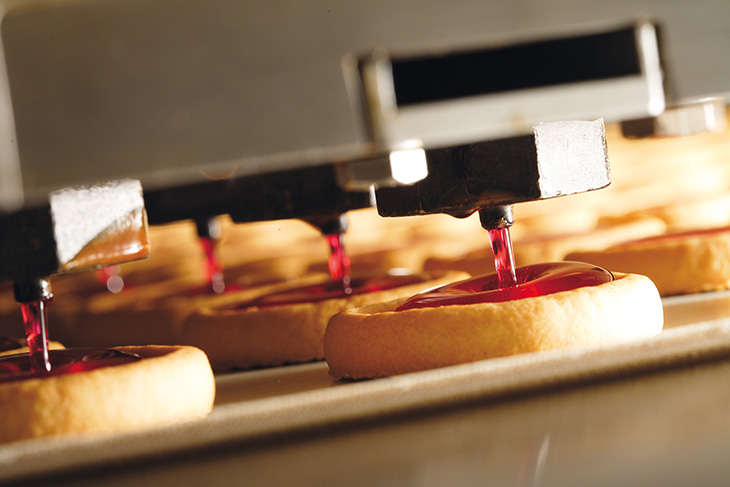

Algra tec AG has been manufacturing operating systems with piezo elements for decades. If these are to be used on metallic surfaces, problems can arise with stainless steel with material thicknesses from as little as 0.8 mm. Piezo elements also usually have a high lead content, which can be assessed critically from an environmental point of view. The company therefore decided to develop an alternative. “The new DYNAFORCE touch control system is no longer based on the widely used piezo elements, but on strain gauges,” explains Fajardo. “That is, touching a button produces a change in electrical resistance. Specially programmed algorithms can reliably evaluate these changes, with the result that false triggers are suppressed.” The sensors register even the smallest surface bending when the buttons are touched and even react under special environmental conditions. All IP protection classes can be included. There is no problem operating wet control surfaces with or without gloves. This makes it much easier to use, for example, in the food industry, in everyday medical practice, in public toilets, on transport or in the operation of kitchen appliances and bathroom fittings. Likewise, full functionality is ensured even at high or particularly low temperatures in a range from -40°C to +85°C.

DYNAFORCE is very easy to install. The module can simply be glued to the back of the desired surface, the optimum thickness of which varies depending on the material. For example, material thicknesses of up to 1 mm are ideal with stainless steel, aluminium and glass; thicker materials of 2 - 3 mm can also be used with plastics. Even wood can be used as a surface material: materials as much as 4 mm thick proved reliable for use. This means there are hardly any restrictions on the choice of a suitable front panel. As a result, it is not just unusual design wishes that can be achieved. “Users can also use particularly smooth and easy-to-clean materials, for example,” explains Fajardo. “This offers great benefits, especially for companies in industries with very stringent hygienic requirements.” This is also helped by the fact that the operating surfaces do not have any dirt-collecting edges on which microorganisms can settle, thanks to the printed circuit board mounted on the back. Assembling the PCB itself is just as easy, because the fitter only has to remove the peel-off foil from the module, align it and then press it on firmly. No screws or other tools are needed, leaving the control element ready for use within a very short time. DYNAFORCE has no moving parts, so there is no wear and tear to worry about. Even after more than 10 million test cycles, the modules still function perfectly.

Greater range of functions thanks to button-touch evaluation

“As well as having a wider choice of material, the user also has plenty of freedom in the arrangement of the buttons,” Fajardo reports. “The minimum centre-to-centre distance between two buttons measured needs to be at least 12 mm – depending on the chosen material thickness. Even so, countless designs can be implemented.” The sensors automatically detect whether a user presses the button directly or touches the user interface elsewhere. This ensures that the required function is only triggered if the respective button has been pressed. The high sensitivity of the sensors also makes it possible to determine exactly which button pressed is necessary to receive feedback. The button sensitivity can be selected from 50 g upwards; no upper limit is defined and it can be set individually for each button.

The demo and developer kit is a good choice for those who are uncertain about their own requirements and the functions they need to implement with DYNAFORCE. “The kit provides a particularly good impression of the range of functions,” explains Fajardo. Using the DesignStudio software for Windows (included with the kit), an operating demo module and several button modules, it is easy to assign functions to the operating elements on the PC and test them in practice.” Users can also try out whether, for example, haptic, optical or acoustic button feedback suits their purposes best and thus get a good overview of the best functions for their own application. When it comes to implementing a specific project, Algra tec AG gives comprehensive advice to companies on the next steps and delivers the custom PCBs. “This approach allows companies to decide at their leisure what the operating system should look like later on,” explains Fajardo. “This not only speeds up the entire project process, but also ensures that the finished product meets all functional and design requirements,” Fajardo concludes.